What is Membrane sails?

Membrane sails are made from fibers arranged in a custom design to withstand the stresses of sailing. The 4D membrane is a composite material with fibers sandwiched between two films, engineered for optimal performance, shape retention, and lightness. The 4D design strategically places fibers where the sail experiences the greatest forces. Components and fibers are carefully selected based on the sail’s purpose, making the 4D membrane adaptable to various sailing conditions and ensuring reliability for sailors.

How do we make Membrane Sails?

A layer of Mylar film or taffeta is laminated onto the sail, followed by automatic placement of curved fibers along designated paths. The inner filaments remain dry for easy folding, while the outer fibers are bonded to optimize grid resistance.

Our polyester two-component adhesive minimizes the use of glue, resulting in stronger, lighter materials. Unlike thermoplastic methods, our bonding process is irreversible once completed.

After the second skin is applied, powerful vacuum pumps remove air between the sealed layers. MEMBRANE uses infrared variable-temperature lamps to liquefy, rather than activate, the resin, ensuring even heating across the entire sail.

High-pressure rollers (up to 90,000 kg/sqm) follow the infrared lamps to remove air pockets and compact the layers, allowing for greater fiber concentration in high-load areas. This pressure is crucial in laminating Dyneema fibers.

We use a flat vacuum cooling process to ensure a uniform monolithic composite, avoiding distortions caused by 3D thermo-moulding. For Dyneema membranes, the post-curing process can last several days, ensuring design repeatability and perfect sail symmetry on both tacks. The sail’s final shape is not influenced by distortions over a 3D mould.

How to take care of Membrane Sails?

Membrane sails cannot have too much salt left over. As they are made of aramid material, which is highly sensitive to sunlight, it is important to be careful about the impact of UV rays on them. Therefore, it is crucial to use awnings and covers even on the rolled-up headsails to prevent any damage. However, filamentary membranes do not pose the risk of delamination, which eliminates a major degradation factor.

More information

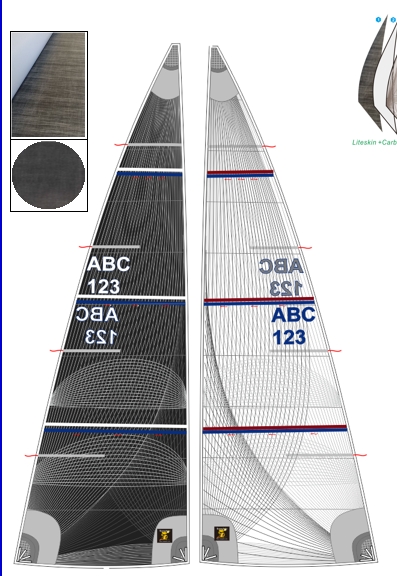

Membrane 4D Mainsail

Designed for sailors seeking top performance and durability, the Membrane 4D Mainsail is ideal for racing and high-speed sailing, with a focus on precision and control.

Sailcloth:

- Carbon with Technora X ply for strength and lightweight performance

- Dyneema with Mylar laminate for durability and stretch resistance

- DCXi-L Film for racing-level weight savings

Key Features:

- Carbon and Technora fiber mix for strength, lightweight performance, and durability.

- Membrane 4D sailcut enhances sail shape retention for greater speed and control.

- Optimized for light to medium wind conditions, perfect for competitive sailing.

Options

Sailcut Options:

- Tri-radial for durability and optimized sail shape

- Cross-cut for simplicity and versatility

Battens:

- Full battens for maximum shape retention

- Partial battens for flexibility and easier handling

Radial Patches: Reinforced in high-load areas for durability and wear resistance

Additional Customizations:

- Reefing points for wind adaptability

- Cunningham system for enhanced sail trim control

- UV protection strips for extended sail life

- Luff slides or bolt rope for ease of handling or streamlined finish