What is Membrane sails?

Sails are made from membranes composed of fibers specifically designed to handle sailing stresses. The D4 membrane, a composite material with fibers sandwiched between two films, ensures optimal performance, shape retention, and lightness. By placing fibers where forces are strongest, D4 adapts to various sailing conditions, offering durability and reliability for sailors.

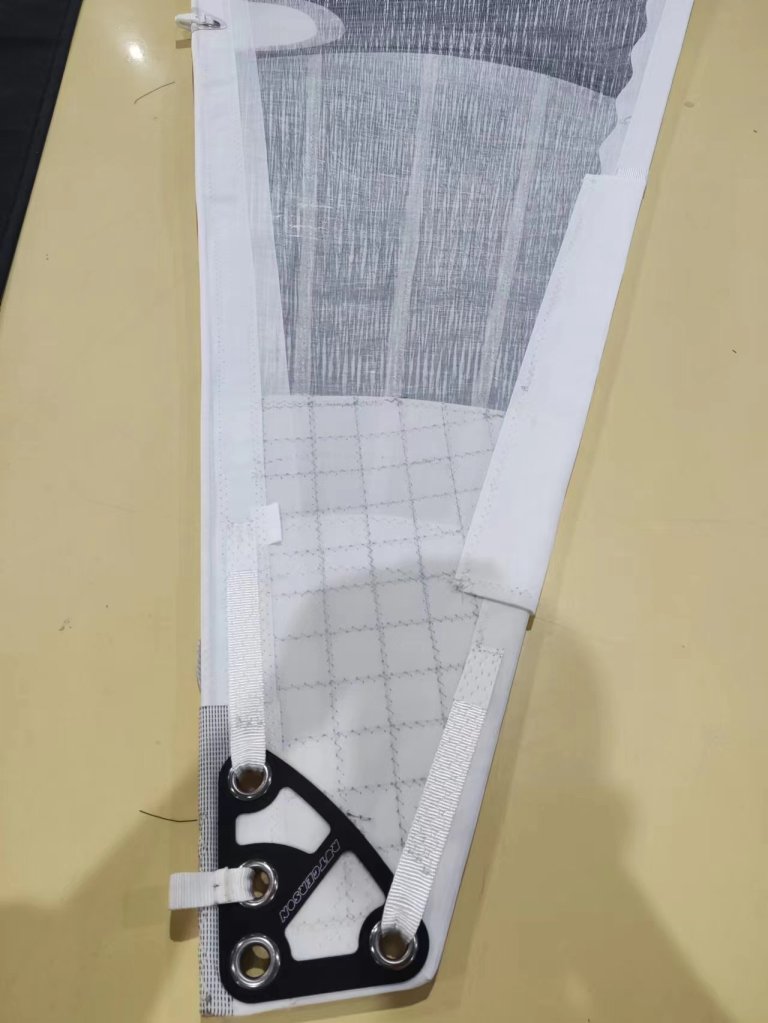

Standard Membrane 4D Headsail

The Membrane 4D Headsail is designed for racing enthusiasts who prioritize precision and reliability. Using advanced materials, it maximizes performance.

- Sailcloth: Light/Medium Racing Clear Film, Carbon with Technora mix, Technora X ply.

Key Features:

- Carbon and Technora fiber mix for exceptional strength and lightweight performance.

- Technora X ply for enhanced durability and stretch resistance.

- Reefs for adaptability and improved sail control in varying wind conditions.

FAQ

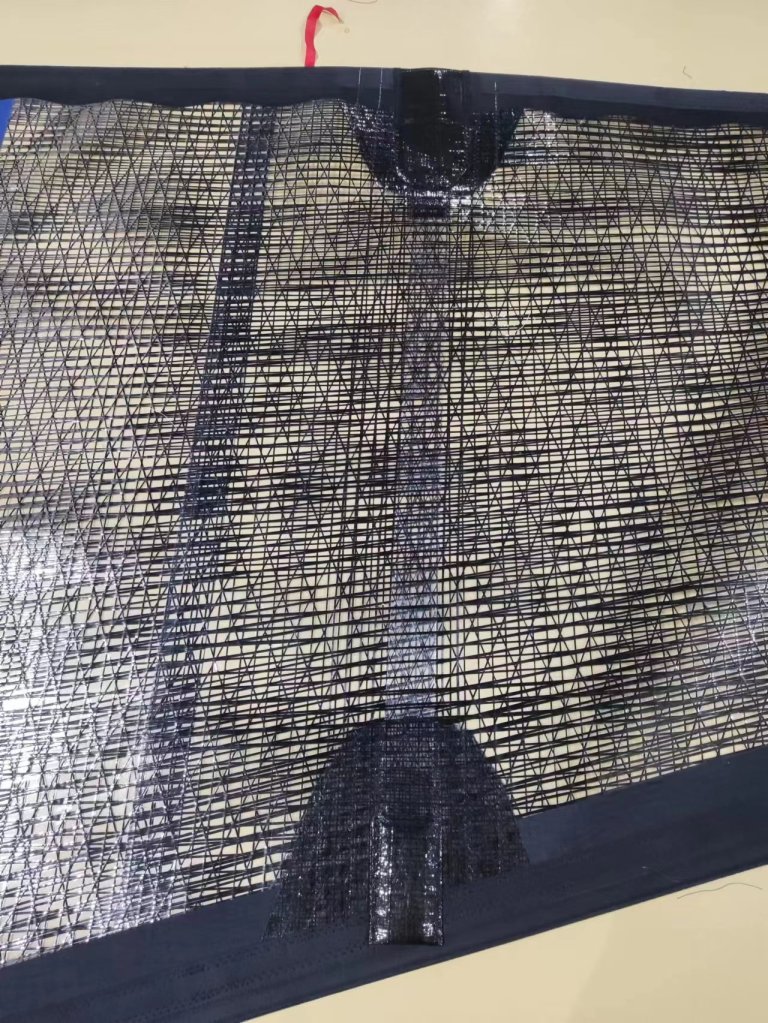

How do we make membrane sails?

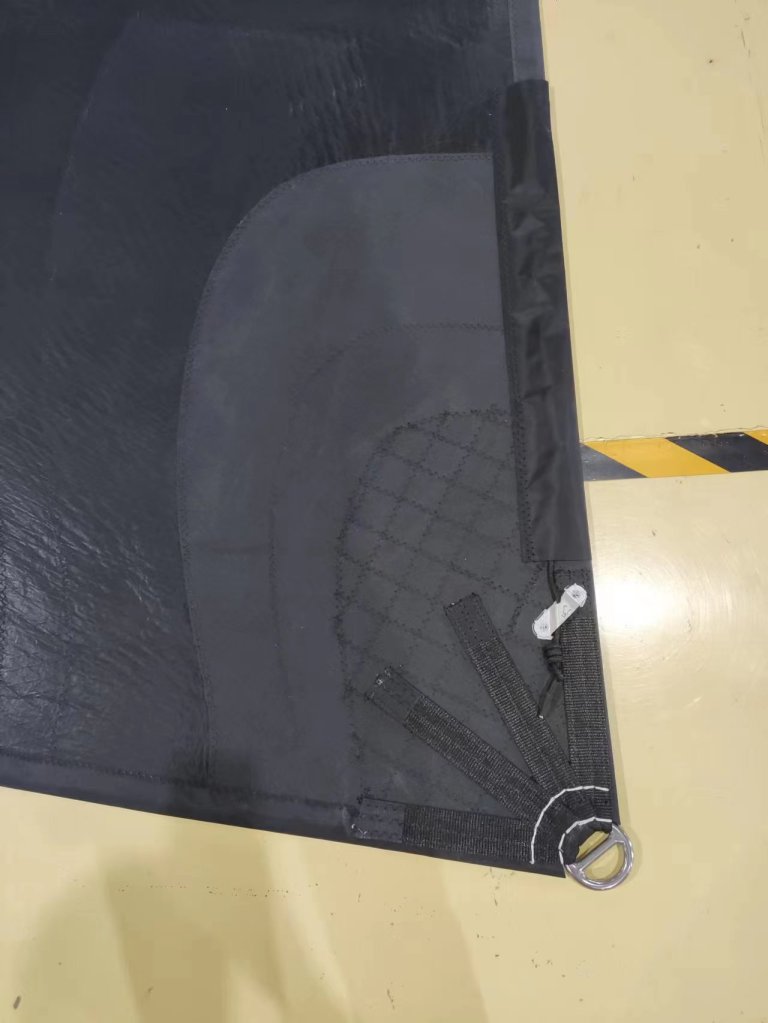

The production of membrane sails begins with applying a layer of Mylar film or taffeta onto the surface. Next, curved fibres are carefully placed along designated paths using an automated machine. The internal fibres remain dry and flexible, while the outer surfaces are bonded together to ensure optimal grid strength.

A two-part polyester adhesive is used in the process, which reduces the amount of adhesive needed, making the sail both lighter and stronger. This bonding process is irreversible, unlike thermoplastic methods. After applying the second skin, powerful vacuum pumps extract the air between the two layers to create a sealed structure.

Infrared, variable-temperature lamps are then used to liquefy the resin, ensuring even heating across the entire surface without causing any distortion. High-pressure rollers follow this step, compacting the various layers and concentrating the fibres in the sail’s load-bearing areas. Dyneema fibres are laminated into the sail for additional strength.

The final step involves a flat vacuum cooling process that stabilizes the composite material. For Dyneema membranes, this post-curing phase can take several days to complete, ensuring the material reaches its full strength and durability.