Revolutionize sail-manufacturing

BUILT TO LAST

Mylar has its place in various industries, but when it comes to performance sails, it falls short. EnduraTech’s innovative construction method completely removes Mylar, producing sails that are exceptionally resistant to stretching, UV exposure, and—most importantly—delamination.

With our zero Mylar design, EnduraTech sails maintain their shape and withstand harsh elements, ensuring reliable and consistent performance throughout their long lifespan.

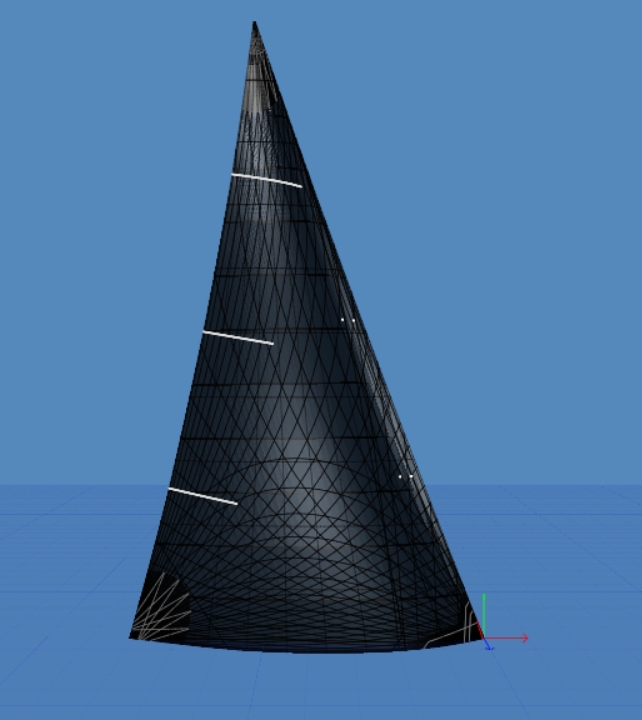

AERODYNAMIC

EnduraTech sails are crafted for maximum efficiency, reducing drag and enhancing drive across a broad range of wind conditions. Our design team utilizes advanced software and precision 3D molds to engineer sails that are tailored to the aerodynamics of each boat type. The result is a durable, one-piece sail that resists stretch and performs longer than traditional sails.

LIGHTER, BETTER

EnduraTech uses the world’s lightest and strongest filaments—thinner than a human hair. Built with filaments thinner than a human hair, our sails are engineered to be 20% lighter for the same strength or 20% stronger for the same weight compared to competitors. Without Mylar, every ounce of an EnduraTech sail is dedicated to enhancing performance.

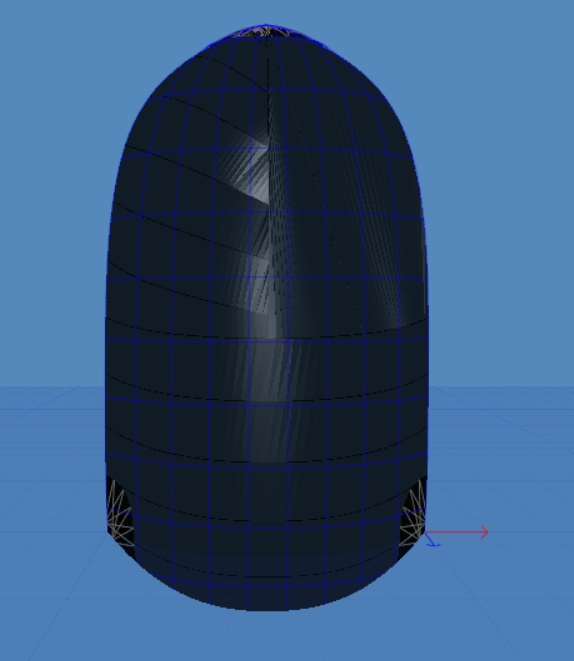

Post-Cured Shaping

EnduraTech™ membranes are engineered as a single, continuous structure directly on a full-scale 3D mould, eliminating the need for secondary shaping seams or panel assembly. Unlike traditional construction methods that laminate flat sections before joining, Loong Sails employs pre-shaped curing, in which every fibre is laid to match the sail’s designed flying shape from the outset.

After the fibre layout is complete, the membrane is subjected to high-pressure thermal curing, locking in the 3D profile at the molecular level. This eliminates broadseam-induced distortion and ensures that luff curves, twist gradients, and projected camber profiles are captured with millimetric precision. As a result, EnduraTech™ sails deliver a true-to-design aerodynamic shape straight out of the press—without requiring post-lamination shaping, flattening, or reshaping during finishing.

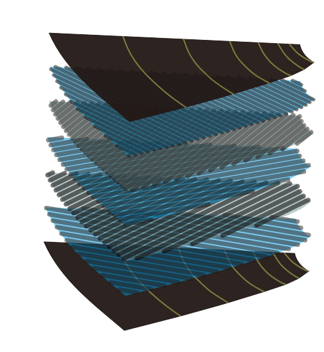

Lamination

EnduraTech™ is a film-free composite membrane constructed through a high-pressure fusion process that replaces traditional Mylar® films with a monolithic resin-fibre architecture. Unlike conventional laminates, which rely on adhesive bonding between layered sheets, EnduraTech integrates structural fibres directly into a unified matrix, producing a more stable, durable, and shape-retaining sail structure.

At the core of the membrane is a custom fibre array laid precisely along load paths, using high-tensile filaments such as Technora®, carbon, or high-modulus polyester. These fibres are tensioned and positioned onto a thermo-formed 3D mould according to exact sail design specifications. Rather than using surplus adhesive or film, the fibres are lightly primed with a reactive thermoset resin to prevent excess saturation, reduce weight, and preserve flexibility.

Verification

The development and refinement of EnduraTech™ membrane sails at Loong Sails has been grounded in extensive real-world testing across multiple platforms. Verification takes place aboard both offshore cruisers and competitive one-design fleets, sailing over 8,000 cumulative nautical miles in varied wind angles, wave states, and load cycles. This robust exposure provides a controlled yet demanding environment in which to validate structural integrity, aerodynamic shape retention, and durability over time.

PROCESS

The process starts with selecting a durable surface, typically 10-30 meters long. X-Ply yarns are laid as a 2-ply support layer, followed by primary yarns like polyester or Technora. Around 500 to 1,100 filaments are used, depending on the sail’s strength needs.

Custom layouts are added for features like batten pockets and loops. The process is repeated in reverse, creating a 4-ply structure for even strength.

The sail is then laminated under 16 tonnes of pressure for 2-3 hours, sealing the layers for durability. Finally, expert sailmakers complete the final hand-finishing steps.

EnduraTech sails